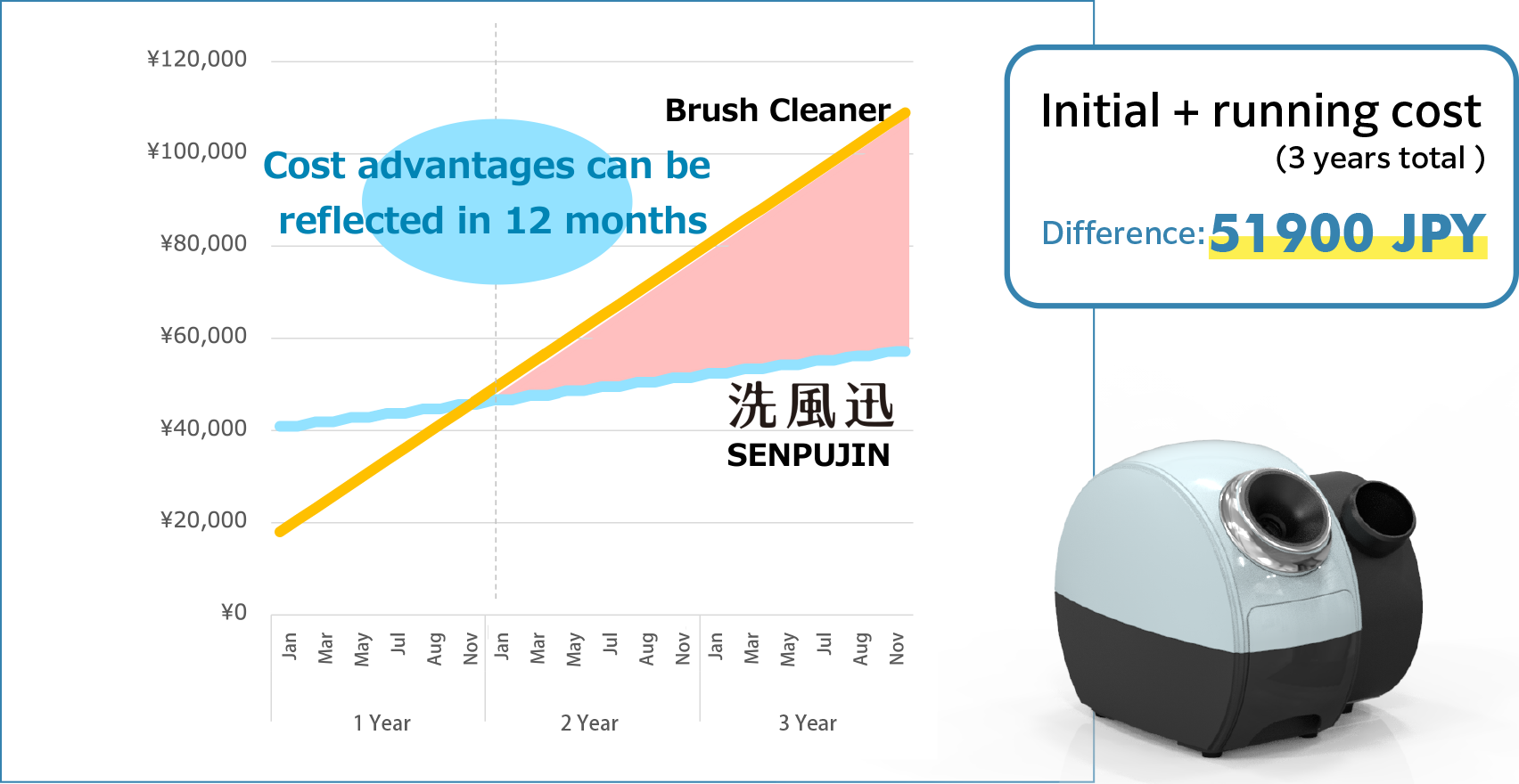

Introduction of Cyclone rype Solder Cleaner

SENPUJIN

※Mail Program

Sales start in 2023

Applicable to various shapes

of solder gun head

Non-contact type, reducing wiping wear

No need for cleaning consumables,the equipment is maintenance-free

We have developed a whirlwind soldering head cleaner through the simultaneous output of air from multiple angles to generate powerful power. The new development of non-contact soldering head cleaner no longer uses the original cleaning consumables and breaks the inherent wiping and cleaning mode. Even if it is frequently used in a short time, it will not affect the cleaning ability.

It is only necessary to empty the collection box in the equipment to keep the work site clean and tidy.

Solve problems in soldering operation

Do you have the following trouble?

There is a lot of exchange frequency early on consumption of the tip.

Solder head needs frequent replacement due to aging

Replacement and maintenance of cleaning sponge and wire

Solve!

Need not wipe

the solder head,

reduce the wear

Solve!

Keep

the work site

clean

Solve!

Maintenance free

without

cleaning brush

- Extend the service time of soldering head

- Since the temperature change of the tip is small, it moves to the work quickly.

- Cleaning time is shortened.

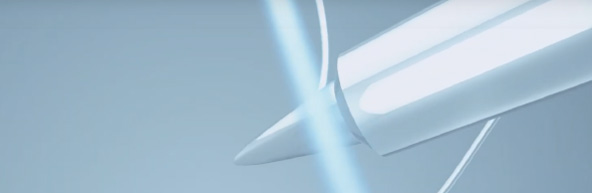

Total cost comparison (compared with the equipment used by the agency)

| Cleaner Name | Frequency of changing rotary brush | Frequency of changing soldering iron tip |

| Brush Cleaner | Once every month | Once every month |

| SENPUJIN | no need | Once every 2 months |

The use of the hair brush is very low, and the rate of wear

※Mail Program

Question and Answer

| Q1 | Power environment |

| A1 | AC100V ~ 240V 50/60Hz |

| Q2 | Required air pressure |

| A2 | Air pressure 0.3 ~ 0.5MP.Oil free is recommended.Install within 5 meters from the regulator. |

| Q3 | Size of Solder Header |

| A3 | It can be used for soldering of 12mm or less.(Including heater shaft) |

| Q4 | How to clean it? |

| A4 | After work, please rinse the insert with alcohol. Remove the solder in the dust box. |

About demonstration machine.Please contact me.

Product specification

Power Supply: 100V~240V 50/60Hz

Air Pressure: 0.3 ~ 0.5MP

Max size of solder head:φ12, dimension:131mm(W)×156mm(D)×131mm(H)※Included Solder holder

Color: 8 color

※Mail Program

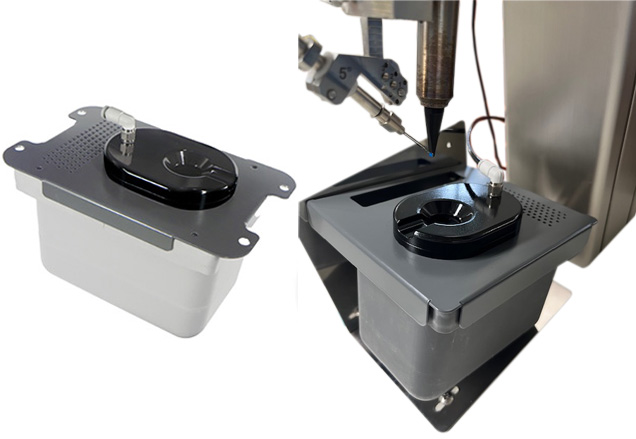

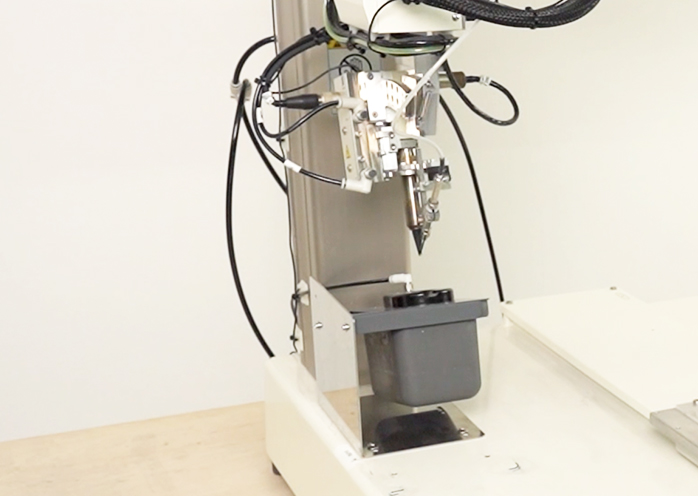

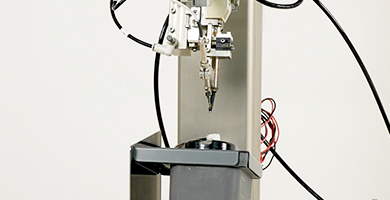

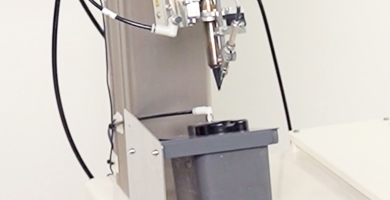

Introduction of Rudra2,

an iron tip cleaner for soldering robots.

Rudra2

With the patented technology of air cleaning, the solder slag is collected in the waste bin at the same time as the iron head is cleaned, which prevents the solder slag from flying away.

Suitable for all shapes of ironing heads.

Cleaner specially developed for soldering heads used in welding robots.Relying on the same patented technology as SENPUJIN, removal of residual stains on the surface of the iron head by rotary air and centralized collection of the stains avoided. The dirt scatters inside the device to reduce the cleaning pressure.Compatible with all shapes of iron head.

※Mail Program

Features of product

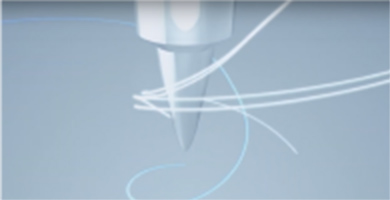

“Rudra2” is a cyclone type soldering iron cleaner for the soldering robot.

The feature is that there is no need to adjust the air blowing nozzle and the tip of the soldering iron is cleaned by utilizing the cyclonic airflow.

The main feature of this product is that there is no repetition of solder dust and it does not affect the cleaning around the robot or the product board to be soldered.

Benefits of product introduction

No solder dust are scattered.

Even if the tip shape is changed, it can be cleaned without adjustment.

Welding Robot Soldering Head Cleaner [Rudra2] is recommended for the following enterprises

- Substrate Surface Mounting Part Processing Enterprise.

- Enterprises with Own Substrate Product Mounting such as Household Appliances Brand and Machinery Equipment Brand.

- Enterprises using various brands of welding robots.

- Enterprises that use welding robots to build in-community production lines.

One-stop solution for cleaning and deterioration and aging of electric cautery head

Reduce the complexity of cleaning iron head.

Reduce the purchase cost of iron head consumables.

Slow down the aging of the iron head and reduce the frequency of replacement.

Remove the solder residue from the soldering head thoroughly.

Prevent the scattering of solder slag when cleaning the head.

From Order Purchase to Delivery Related

(1) Please contact directly by phone or fill in the purchase requirements Online.

(2) We will have someone to contact you in accordance with your needs.

We will meet your needs! Please feel free to contact us.

TEL:+81-44-511-5511

FAX:+81-44-511-5513